Categories

- Blog (58)

- News & Events (34)

Abstract: Diesel generators make regular and rhythmic sounds when they are running normally. When the parts are severely worn, the coordination changes, the repairs and adjustments are not correct, and the connections are loose, it is often accompanied by abnormal sounds from the parts, such as diesel generators. The metal knocking sound when the generator is running, the abnormal burning sound and the air leakage sound, etc. If there is such an abnormal sound, it means that the diesel generator is faulty and should be stopped for inspection and repair, otherwise the accident will be further aggravated. When the diesel generator is abnormal during operation, it will usually make abnormal noises. Usually, you can know whether the diesel generator is faulty by “auscultating” the diesel generator. If you hear abnormal noise, stop it immediately. Check the diesel generator to find out the cause.

1. Common abnormal noise phenomenon

1. When the load of the diesel generator changes suddenly, a short, blunt knocking sound of “empty, empty, empty” can be clearly heard near the crankcase (in the range from the middle to the lower part of the cylinder block)

And change sharply with the increase of load or speed

The noise increases, and the sound can be heard more clearly when the oil filler cap is opened, but it is not obvious when there is no load. This is due to the excessive wear of the connecting rod bushing and the large matching gap between the connecting rod bushing and the crankshaft connecting rod journal. Roaring tiles.

2. When the front side of the engine and the timing gear chamber make rhythmic “ye la la, hua la” sounds, the sound is louder when running at low speed, which is caused by the excessive wear gap between the timing gear shaft and the bushing; the diesel generator is idling When running, there is a rhythmic “crack, cluck” sound at the timing gear chamber and the side of the camshaft. The sound is more prominent at low and medium speeds, and becomes messy and broken at high speeds. If the noise is heavy under heavy load Enhanced, this is the knocking sound caused by the excessive meshing gap of the timing gear, the collision of the tooth surfaces, or the abnormal meshing of the two gears after the sleeve is worn; the diesel generator produces violent vibration sound during operation, and it is difficult to operate, this is the timing The gear mark is installed incorrectly, or the weight of the balance weight is wrong, or the bearing of the balance shaft is seriously worn.

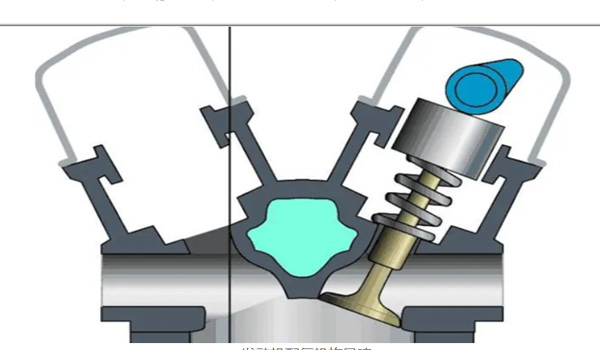

3. There is a sound of “cha, cha, cha” at the cylinder head, accompanied by the sound of “shh, shh, shh”. When the engine is about to turn off, the sound is more obvious. The impact sound between the ring, the valve and the cylinder head; when the diesel generator makes a “chacha” sound like broken tiles at the valve cover, or the sound of two springs hitting, at the same time the exhaust pipe Intermittent explosion sounds, diesel generators are unstable, and black smoke is emitted, which is caused by broken valve springs; if there is a rough and sharp “shh, hush, hush” sound at the joint between the cylinder head and the body, and Accompanied by blow-by gas and smoke, this is caused by the damage of the cylinder head gasket. If you hear the sound of “shh, hush, hush” at the air filter, and the diesel generator is difficult to start, or it runs for a while after starting Touch the intake pipe with your hands for a long time and feel hot. Most of this is caused by valve burnout (corrosion), carbon deposits, and air leakage due to poor sealing; on the upper part of the engine near the fuel injector, you can hear a crisp and heavy “clang” “, clang” impact sound, which changes with the speed change, and the start and combustion are not normal, which may be caused by the drop of the insert in the swirl chamber; when the engine is running, there are low-pitched “Weidang, Weidang” and “Ga, Weidang” “Ga” sound, the sound is much louder than the sound of the main bearing bearing clearance being too large, especially when the speed changes suddenly, which is caused by the loosening of the flywheel fastening nut.

4. When the diesel generator has a heavy and continuous knocking sound at the lower part of the crankcase, the sound is clearly discernible at low speed, and it is more obvious at heavy loads. At the same time, the oil pressure decreases, which is caused by the excessive clearance of the main bearing bush of the crankshaft. Cause; When the engine speed suddenly changes at low speed, there will be a “clang, clang” sound on the upper part of the cylinder, which is caused by the excessive gap between the piston pin and the connecting rod bushing, or the piston pin seat. If the engine is running at high speed, there is a muffled sound of “cracking, thumping”, especially when the throttle is suddenly reduced. This is caused by the excessive axial clearance of the main bearing bush; a roaring and dull “cracking” sound can be heard from the entire length of the cylinder. Knocking sound of “empty dong, kong dong”, and bubbles were found when opening the fuel filler cap (indicating air leakage), which is caused by the excessive gap between the piston and the cylinder liner; The impact sound of is the knocking sound caused by the twisting of the connecting rod causing it to sway during work. The latter two sounds are more clearly heard when changing the speed and are easier to distinguish; along the cylinder There is a sound similar to a small hammer hitting an iron block at the upper and lower places, and blue smoke is emitted from the exhaust pipe of the diesel generator (accompanied by the phenomenon of burning engine oil). It can be concluded that the side clearance of the piston ring is too large or the ring is broken.

Abnormal sound fault solution

1. The fuel injection time of the diesel generator is too early or too late, and there is rhythmic crisp metal knocking sound or low and unclear knocking sound in the cylinder. At this time, the fuel injection advance angle should be adjusted;

2. The wear of the connecting rod bearing bush makes the When the fit gap is too large, the impact sound of the parts can be heard in the crankcase during operation, and a heavy and powerful impact sound can be heard when the diesel generator speed is suddenly reduced

In this situation, the bearing bush should be dismantled and inspected, and if necessary,

should be replaced;

3. The fit between the piston pin and the bushing hole of the small end of the connecting rod is too loose, and there is a light and sharp sound when the diesel generator is running. This sound is especially clear when running at a constant speed. Within the gap range;

4. The gap between the piston and the cylinder liner is too large, and the impact sound can be heard on the outer wall of the cylinder when the diesel generator is running. ;

5. The valve spring of the diesel generator is broken, the tappet is bent, the sleeve of the push rod is worn, and there is a slight rhythmic knocking sound on the whole cylinder. At this time, the parts of the diesel generator should be checked and the damaged parts should be replaced, and the valve should be corrected gap;

6. The radial clearance of the crankshaft rolling main bearing is too small, and the diesel generator makes a particularly sharp sound during operation. The sound is clearer when the accelerator is increased; , at this time, stop the machine to check the noisy rolling main bearing, and replace it if necessary;

7. The front and rear thrust bearings of the crankshaft are worn out, and the axial clearance is too large, causing the crankshaft to swim back and forth. When the diesel generator is running, the collision sound of the crankshaft swimming back and forth can be heard. At this time, the axial clearance and the wear degree of the thrust bearing should be checked. , replace if necessary;

8. There is no oil between the rocker arm adjustment screw and the spherical seat of the push rod. When the diesel generator is running, there is an abnormal noise. Fault Analysis The cylinder head can hear a “squeak” sound from dry friction. At this time, the cylinder head cover should be removed.

9. There is an abnormal collision sound when the turbocharger is running. At this time, the bearing should be dismantled and checked for wear and the impeller blades are bent. Measure the abnormal noise of the main diesel generator at the same time. Analyze the gap and make adjustments and replace damaged parts, clean the oil filter of the supercharger and the oil inlet and outlet pipelines, and ensure that the lubricating oil is unblocked when the diesel generator is running.

10. When the valve hits the piston, there is a heavy, uniform and rhythmic knocking sound at the cylinder head during operation. Use your fingers to gently hold the nut of the cylinder head cover and feel a collision. Remove the cylinder head cover and check for collision. Reasons, adjust the valve clearance, if necessary, check the abnormal noise when the diesel generator is running, and analyze whether the piston model is wrongly adjusted. If there is a collision, you can properly dig deep valve pits or add a sheet of The same copper skin gasket as the bottom surface of the cylinder;

11. The gap between the intake and exhaust valves is too large, and there is abnormal noise when the diesel generator is running. Fault Analysis A rhythmic loud noise is heard at the cylinder head. At this time, the valve gap should be re-adjusted;

12. The transmission gear is worn, the gap is too large, and there is an abnormal sound at the front cover. When the diesel generator suddenly slows down, the impact sound can be heard. At this time, the gear gap should be adjusted and the gear should be replaced according to the wear condition.