Categories

- Blog (58)

- News & Events (34)

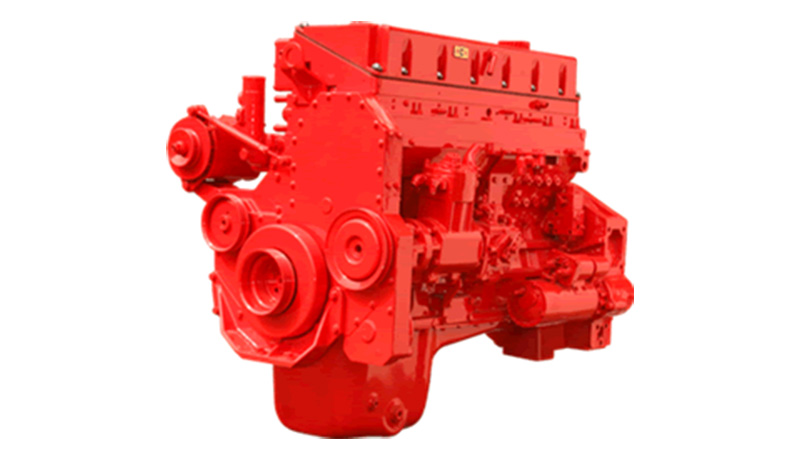

Cummins M11 series engine product performance characteristics

• Advanced technology, world quality

Cummins leading technology, widely used in North America and Europe heavy truck.

• Super power, green environmental protection

Large displacement: while meeting the power requirements of heavy truck, the engine has higher reliability, durability and safety.

High power: maximum power up to 420 horsepower, to meet the modern logistics fast, efficient and safe requirements.

Large torque: maximum torque 1650n. m, strong power, meet the requirements of heavy truck starting and long uphill.

Light weight: weight is only 940 kg, power weight ratio is large.

Excellent emission: the engine has good steady-state exhaust smoke at full load and meets euro 3 standard.

• Low fuel consumption and good economy

Cummins PT fuel system, ultra-high injection pressure, to ensure good engine atomization, full combustion.

The efficient Holset exhaust gas turbocharger ensures a fuller intake, increasing engine efficiency, further improving combustion and reducing engine specific fuel consumption.

Air – to – air intercooling technology to ensure full air intake, better fuel economy.

STC timing system ensures better combustion under high and low load conditions.

• Compact structure and easy maintenance

Replaceable wet cylinder liner, good heat dissipation effect, easy to replace.

All models of parts and components of strong versatility, high degree of serialization, easy maintenance.

Cylinder body and cylinder head adopt built-in pressure lubricating oil channel, compact structure, low failure rate.

• Advanced design and reliable performance

Cylinder block: made of high strength alloy cast iron, good rigidity, small vibration, low noise.

Cylinder head: each cylinder four valve design, optimization of air/fuel mixture ratio, effectively improve combustion and emissions; Integral cylinder head, easy maintenance.

Camshaft: Single camshaft design provides precise control of valve and injection timing. Optimized CAM profile reduces impact force and improves reliability and durability.

Crankshaft: integral crankshaft made of high strength forged steel. Induction hardening process of fillet and journal ensures higher fatigue strength of crankshaft.

Piston: using the latest aluminum alloy casting technology, ω -type head and articulated design can compensate for heat expansion and cold contraction to ensure good fit.

• Professional configuration with excellent quality

Lubrication system: all moving parts are forced lubrication; Large capacity gear pumps provide pressure lubricating oil to lubricate bearings and cool pistons; Oil cooler, compound filter to maintain good oil condition.

Fuel system: Cummins PT fuel system, optimized combustion, power surge; STC distributed timing system ensures better combustion in all working conditions; Low pressure oil supply system, one-way fuel circuit, safe and reliable.

Cooling system: gear centrifugal water pump forced water cooling, large flow channel design, good cooling effect; Rotary water filter and special DCA additive can effectively prevent corrosion and cavitation, control coolant acidity and remove impurities.

Intake and exhaust system: Efficient Holset exhaust supercharger to further improve combustion; Pressure pulse exhaust pipe can make full use of exhaust energy and improve engine efficiency; Air to air intercooling technology ensures better fuel economy and emissions.

• Mature products, worldwide reputation

Widely used: since the joint venture in 1995, M11 series engines have been widely used in tractors, cement mixers, mining vehicles, construction machinery, power generation, Marine power and other fields; Establish strategic partnership with key customers.

High reputation: As one of the main models in cummins family, M11 engine is highly recognized by customers in various fields for its powerful power, ultra-low fuel consumption, high reliability and low maintenance cost.

Technology upgrade: Air-to-air intercooling technology improves engine reliability, power performance, fuel economy and emissions. The electronic fuel system further enhances the M11 engine’s leading position in China’s high-horsepower engine manufacturing industry.